- Ceramics[10]

- Carbon[10]

- Asbestos Products[1]

- Water Treatment[17]

- Refrigeration & Heat Exchange Parts[2]

- Gas Disposal[4]

- Refractory[2]

- Catalyst[4]

- Other Chemical Equipment[3]

- Home Textile Product Machinery Parts[1]

- Other Plastic Products[10]

- Other Petrochemical Related Products[6]

- Separation Equipment[5]

- Other Metals & Metal Products[7]

- Chemical Process Equipment Parts[8]

- Other Steel Products[1]

- Other Packaging Materials[1]

- Plastic Nets[1]

- Heat Transfer Equipment[1]

- Chemical Auxiliary Agent[10]

- Oxide[2]

- Other Environmental Products[1]

- Water Filters[3]

- Contact Person : Mr. Lau Robin

- Company Name : Pingxiang Fxsino Petrochemical Packing Co., Ltd.

- Tel : 86-799-6888511

- Fax : 86-799-6831452

- Address : Jiangxi,Pingxiang,Sanpu Lane, East Door Area, Pingxiang City, Jiangxi Province

- Country/Region : China

- Zip : 337042

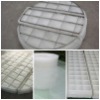

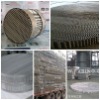

Plastic wire-mesh demister for seperation

PP Wire Mesh Demister:

Demisters are made up from knitted materials with interlocking asymmetrical loops of metal or plastic with typical wire diameters being 0.1 – 0.3mm. By careful choice of wire diameter, Knitwire Products have produced knitted mesh demisters with extremely high free volumes (typically 98-99%) along with very high removal efficiencies and low pressure drop.

Along with wire diameter and mesh density, another important parameter in design and operation is the vapour velocity. This can be controlled by careful selection of the mesh area. Optimal area will depend on operating temperature, pressure and pressure drop. Under normal operating conditions, 99% + removal efficiency can be achieved with a pressure drop of less than 250 Pascals.

According to Polypropylene’s feature, include in non-toxic, odorless, tasteless cream color high crystallization polymer, density only then 0.90~0.91g/cm3,

The sophisticated aerodynamic design of the profiles causes the elimination of liquid droplets by inertial forces. The profiles are designed with a main drain channel to capture the bulk of the captured liquid and a number of small drain channels to prevent re-entrainment downstream of the venture like throat. By the combination of drain channels, the captured liquid droplets prevented from re-entering.

Typical Applications:

1. Eliminate liquid droplets and prevent products losses

2. Scrub pollutants to meet stringent emission requirements

3. Remove liquid contamination from off-gas

4. Reduce downstream fouling dur to TDS

5. Enhance overhead product quality

6. Prevent carryover of mist with dissolved and suspended solids

7. Improve efficiency and provide high-purity condensate

8. Separate condensate and oil from the incoming gas stream

Plastic wire-mesh demister for seperation